In an increasingly unstable economic context, industrial companies are facing major challenges. Budget restrictions, the pressure to maintain high safety standards, and the need to comply with strict regulations are creating considerable strain on available resources. In times of financial crisis, it becomes imperative to find innovative solutions to reduce costs while maintaining essential industrial inspections. The use of drones is proving to be an ideal answer, bringing considerable benefits in terms of profitability and efficiency.

Mandatory inspections, even in times of crisis

Regardless of the economic climate, industrial infrastructure inspections must be maintained to ensure the safety and proper functioning of facilities. Regular and rigorous inspections are often required by regulations to prevent costly accidents, serious failures, or production interruptions. However, in times of budgetary constraints, it is becoming increasingly difficult for companies to finance these costly inspections using traditional methods.

Prohibitive costs of conventional methods

Traditional industrial inspections are often complex and require significant human and material resources. They typically involve the installation of scaffolding, the use of cranes or the deployment of specialized teams to reach difficult areas. These operations, costly in terms of time and labor, significantly increase the operational expenses of companies.

In times of financial crisis, the search for cheaper alternatives becomes crucial. Companies must face the harsh reality of reducing costs while ensuring the security of their infrastructure. This is where innovation, especially in the form of drones, comes into play to offer solutions that meet these requirements more economically.

Technological innovation as a lever for performance

In times of crisis, innovation becomes a strategic tool to maintain competitiveness. The use of drones for industrial inspections is one such innovation that can significantly reduce costs while increasing efficiency. Drones, with their agility and advanced technology, can perform inspections quickly, accurately, and at a lower cost.

A cost-effective and efficient alternative

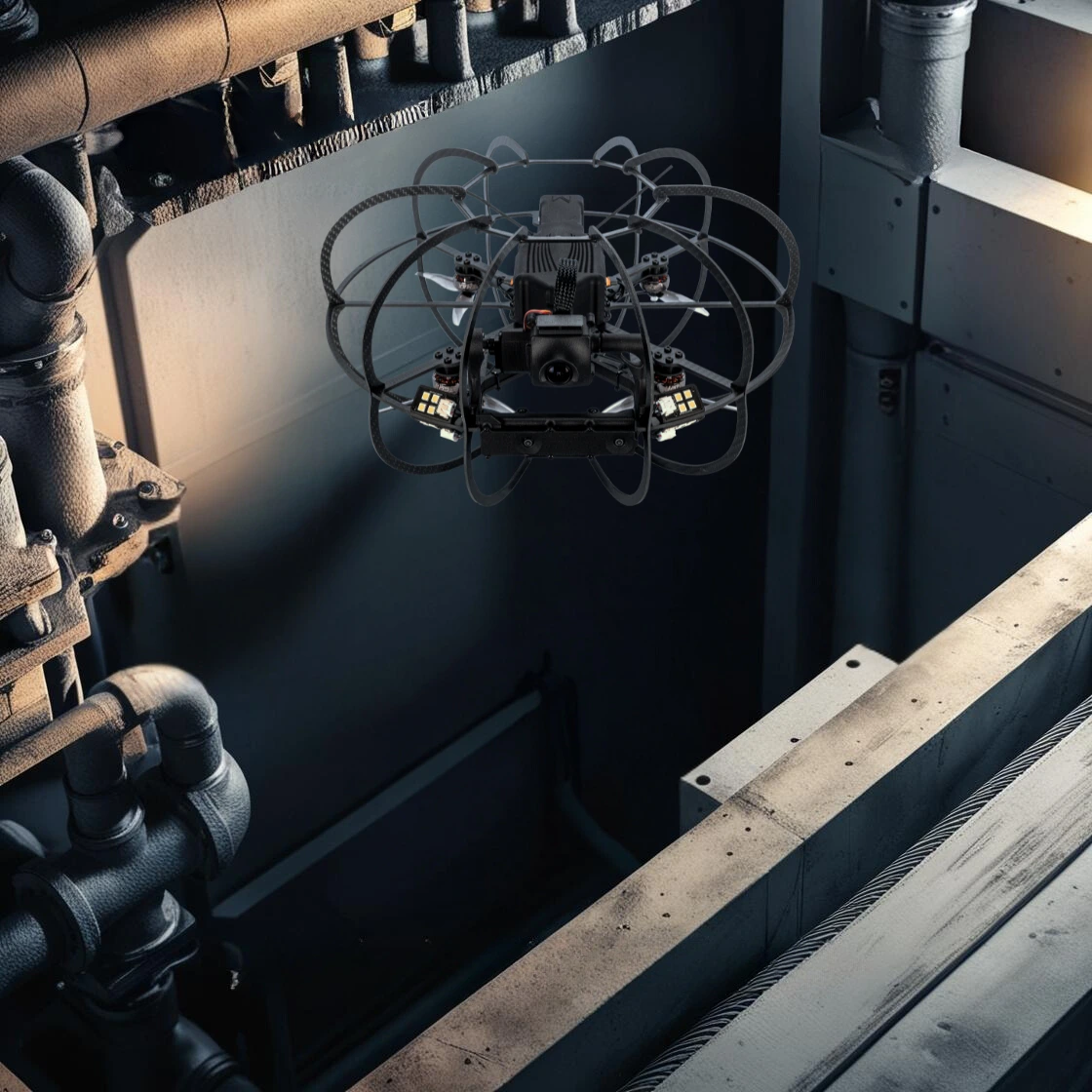

Drones represent an economical and practical solution for companies looking to optimize their resources. Unlike traditional methods, drones can be deployed quickly and reach hard-to-reach areas without the need for

costly temporary structures. This helps reduce production disruptions and allows inspections to be carried out in record time.

For example, instead of mobilizing a team for several days to inspect a structure at height, a drone can perform the same task in a few hours. This time saving translates into significant savings, a significant asset for companies in times of economic crisis.

Safety and precision of drone inspections

Beyond their economic aspect, drones bring a major gain in terms of safety. In industrial environments, inspections often expose workers to dangerous situations, such as heights, confined spaces, or contaminated areas. The use of drones eliminates these risks by allowing inspections to be carried out without exposing personnel.

Less risk, more security

One of the key benefits of drones is their ability to access dangerous locations without human intervention. This reduces the risk of workplace accidents and the costs associated with injuries or compensation. In times of crisis, it is essential to minimize these unexpected expenses, as they can weigh heavily on a company’s finances.

In addition, drones are equipped with high-definition cameras and advanced sensors that can capture images and data with high precision. This information is essential for detecting anomalies invisible to the naked eye and for ensuring effective predictive maintenance. This allows companies to anticipate failures before they become costly problems.

Better resource management in times of crisis

The crisis period is pushing companies to review the management of their resources, both human and material. Drones facilitate this optimization by requiring fewer personnel to carry out inspections. Where traditional methods mobilize entire teams, drones only require a few trained operators. This allows human resources to be redeployed to other priority tasks, thus increasing the overall efficiency of the company.

Flexibility and speed of intervention

Drones offer unmatched flexibility. They can be mobilized quickly for emergency inspections, where lengthy and costly preparations would have been necessary before. This speed of intervention minimizes production interruptions and allows companies to remain operational even in times of urgent need.

Multinnov: A response to the challenges of the crisis

It is in this context that Multinnov stands out as a strategic solution for the industry. Specialist in drone technology, Multinnov offers high-performance and reliable machines which perfectly meet the requirements of industrial inspections. Thanks to their drones, companies can not only carry out inspections faster and more safely, but also significantly reduce their costs.

By leveraging Multinnov’s innovations, companies have the opportunity to transform budgetary constraints into competitive advantages. Multinnov’s drones are designed to offer unmatched precision, flexibility of use and maximum safety, allowing manufacturers to maintain their quality standards while optimizing their expenses.

The future of industrial inspections in times of crisis

In times of financial crisis, companies must rethink their methods to remain competitive and profitable. The adoption of inspection drones is an essential solution to reduce costs, ensure the safety of operations and gain efficiency. With players such as Multinnov , companies have advanced technologies that allow them to overcome economic challenges while improving the management of their infrastructures.

Multinnov drones are not just inspection instruments; they are strategic allies for optimized resource management and efficient predictive maintenance. For industrial companies, choosing to invest in these innovations is a decision that guarantees not only survival, but also growth in an uncertain economic environment.