In the construction, industry, energy and infrastructure sectors, working at height is part of everyday life. Yet they remain one of the major causes of serious and sometimes fatal accidents. Falls from scaffolding, roofs or metal structures are among the main occupational hazards identified by health and safety authorities.

Faced with this reality, the question of prevention becomes crucial. It is in this context that inspection drones are gradually becoming a standard tool. Thanks to their maneuverability and ability to capture high-precision images without the direct intervention of an operator on site, drones reduce human risks while optimizing operations. Innovative players such as Multinnovwith its Stereo2drone, are actively contributing to this transformation of practices.

Working at height: an ever-present risk

The figures speak for themselves. According to INRS, falls from height account for almost 11% of accidents at work resulting in more than four days' absence from work, and are the leading cause of fatal accidents. These figures apply to all sectors where work is carried out at height: construction, industrial maintenance, operation of engineering structures, inspection of energy structures and renovation of historic buildings.

The causes of these falls are manifold: failure of protective equipment, poor weather conditions, human error, or inadequate training of teams. Despite increasingly strict safety protocols, the risks remain. Climbing onto a roof to inspect a damaged area, or hoisting yourself onto a pylon to check a structural anomaly, still exposes technicians to considerable danger.

This regulatory and human context is forcing companies to look for alternative solutions. Prevention requires not only training and safety equipment, but also innovation. And this is precisely where drones come into their own.

The drone: a technology now at the service of safety

Once reserved for military or leisure use, drones have now found their way into the professional world. Their use in technical inspections, particularly of hard-to-reach sites, is growing rapidly.

The advantages are manifold. First, there's safety: a drone can operate in a complex environment, at height or in a confined area, without any operator having to be physically exposed to it. There's no need to climb onto a gondola or suspend a rope operator dozens of meters above the ground for a simple visual check. The drone performs the

tracking, captures high-resolution images or video, and transmits the data in real time.

Secondly, it saves considerable time. Where a manual inspection requires several hours of preparation (setting up scaffolding, securing the area, mobilizing several people), a drone mission is often launched in a matter of minutes. The result: a faster, less intrusive intervention, with no prolonged business interruption.

Finally, the economic aspect is not negligible. Less manpower, less logistical equipment, less risk of accidents... all factors which, in the medium term, significantly reduce costs for the company.

Reduce risk with Stereo2 from Multinnov

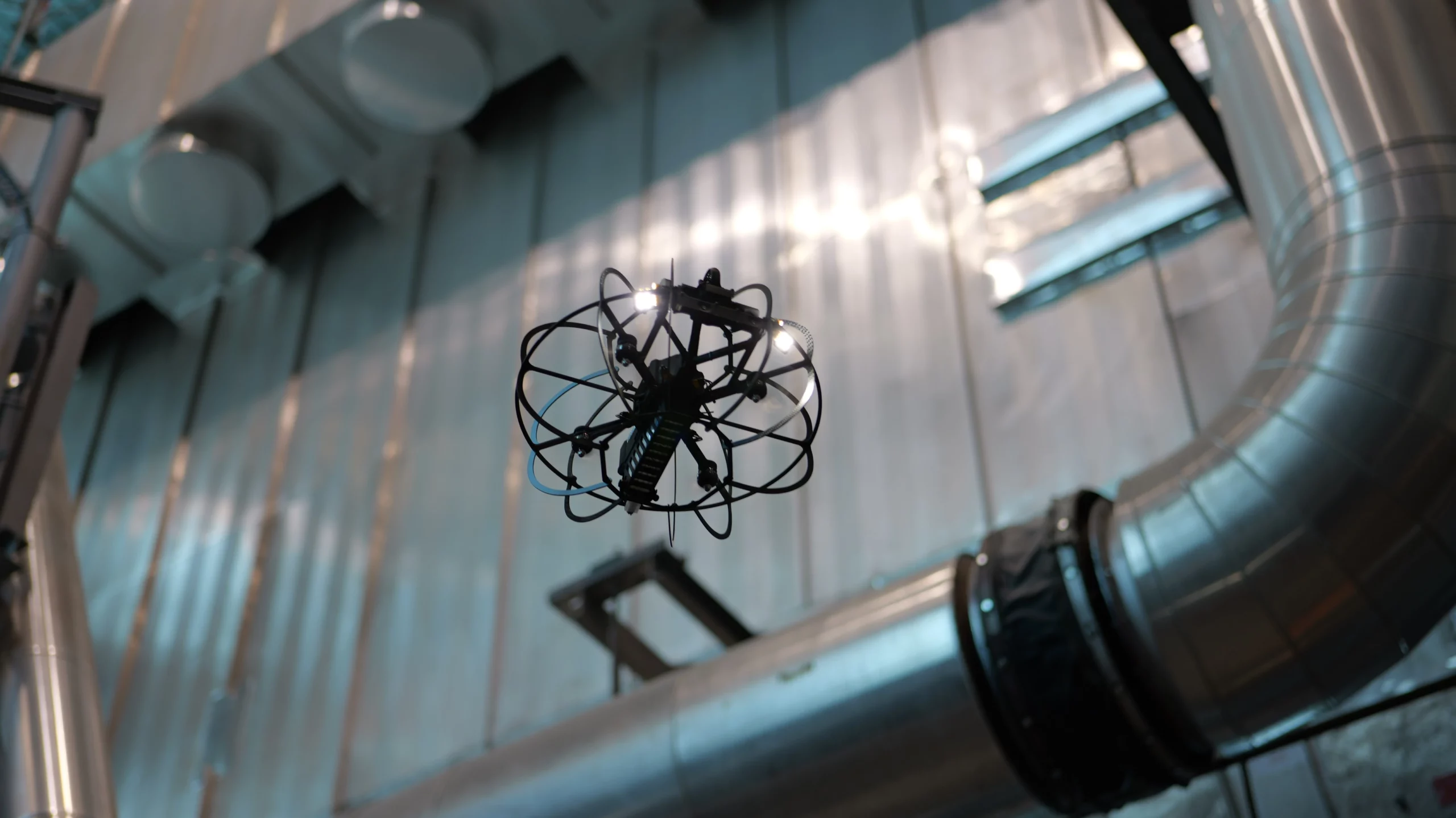

Among the drones specializing in this type of application, the Stereo2designed by Multinnovstands out for its robustness, precision and ability to operate in demanding environments. It's not just a consumer drone for industry, but a technology specifically designed for inspection at height and in confined spaces.

Designed and manufactured in France Stereo2 incorporates features tailored to the real-life needs of professionals. Its stabilized 4K camera enables precise visualization of every detail of a structure, even in low-light conditions. To achieve this, the drone is equipped with four powerful, adjustable LED panels that ensure optimum lighting during missions.

But what makes Stereo2 is its autonomous navigation and ability to operate without GPS. Thanks to its advanced sensors, it can move inside industrial buildings, pipes or under roofs, without losing signal or risking collision. Its carbon-fiber-reinforced structure guarantees excellent resistance to impact, which is essential when working in restricted or congested environments.

Its compact, lightweight design also means it can be set up quickly, even on hard-to-reach sites. It's a true field tool, capable of being used by a small team with minimal training.

In short, the Stereo2 is a perfect example of how technological innovation can directly benefit worker safety, by replacing human intervention in the most critical areas, without sacrificing inspection quality.

Prevention for better cost control

Safety considerations aside, the use of drones like the Stereo2 is part of a clear economic rationale: prevention is better than cure. A workplace accident is costly for a company, both in financial terms and in terms of image. A day's production downtime, compensation for an injured employee, higher insurance costs, or even the loss of a company's reputation are all factors that can have a major impact on the company's bottom line.

administrative inspection following an incident... All these factors weigh heavily in the balance.

By integrating drone inspection into a preventive maintenance strategy, companies can anticipate failures, intervene earlier on detected anomalies, and considerably reduce the costs associated with emergency repairs. What's more, regular inspection provides a clear picture of the condition of infrastructures, facilitating budget planning and decision-making.

From an HR point of view, it's also a strong argument in favor of the company's attractiveness. Offering employees modern, safe tools shows that we take their health seriously. This helps build team loyalty and reinforces the company's in-house safety culture.

Finally, in a context of digital transition and digitization of industrial processes, the use of drones is becoming a central element in the modernization of practices. By combining innovation, efficiency and safety, it enables companies to position themselves as committed, responsible and forward-looking players.

Long considered as experimental tools or reserved for very specific applications, drones are now establishing themselves as standards in the field of height risk prevention. Their ability to accurately inspect inaccessible areas without endangering operators makes them invaluable allies for professionals in the construction, industry and energy sectors.

With solutions like Stereo2 from Multinnovcompanies have a reliable, high-performance tool designed to meet real-world constraints. This "made in France" drone embodies a new generation of equipment serving safety, performance and responsibility.

In view of the human, economic and regulatory issues involved in working at height, TV inspection by drone should no longer be seen as an option, but as a strategic necessity. It's a real lever for progress, helping to prevent accidents, control costs, and support professionals as they move towards a safer, more innovative industry.