/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/ea1426e8-a295-11ef-ab80-0242ac120013/1-1-adobestock845123978jpeg-669623dfaac326-95743537.jpeg)

Inspections of visitable and non‑visable pipes: Appropriate methods and technologies

Pipe inspection is a key component in the maintenance of industrial, drinking water and wastewater infrastructures. Regular inspection of these systems prevents blockages, leaks and other faults, ensuring their smooth operation, lower long‑term maintenance costs and, above all, the safety of people and the environment.

The first essential distinction to be made is between visitable and non‑visitable pipes. Visitable pipes are those whose diameter is large enough for a person to pass through. Depending on the standard, the diameter limit for a visitable pipe is between 1200 mm and 1600 mm. For example, SIARE considers pipes with a diameter of 1600 mm or more to be accessible to human agents, while other infrastructures use a threshold of 1200 mm.

Non‑visitable pipes, on the other hand, have a smaller diameter, ruling out human access. In these cases, specialized robots are essential to ensure accurate and efficient inspection. In visitable pipes, although human access is possible, the current trend is to favor the use of robots to reduce the risk of work‑related accidents in these often confined and dangerous environments.

This article explores traditional and modern methods of pipe inspection, highlighting Multinnov's advanced technological solutions, such as the Roview2.

Traditional pipe inspection methods

Traditional methods of pipe inspection are often laborious and require direct human intervention, with attendant safety risks.

- For visitable pipes: In the past, inspections were carried out by human agents entering the pipe, equipped with lights, hand‑held cameras and protective gear. These direct inspections enable us to get an overview and gather detailed observations, but they are also risky, as the agents are exposed to confined, damp and sometimes toxic environments.

- For non‑visitable pipes: Inspections were limited to the use of cameras pushed onto cables or attached to flexible rods. These devices can capture images, but access is limited, which can leave areas uninspected, and thus failures undetected. This method is also slow, inflexible and limited in terms of inspection depth.

Because of the associated risks and coverage limitations, traditional methods are now giving way to more modern solutions, such as inspection robots, which provide continuous, agent‑safe surveillance.

Modern technologies for pipeline inspection

Technological advances now make it possible to carry out safer, more precise and thorough inspections, thanks to sophisticated inspection robots.

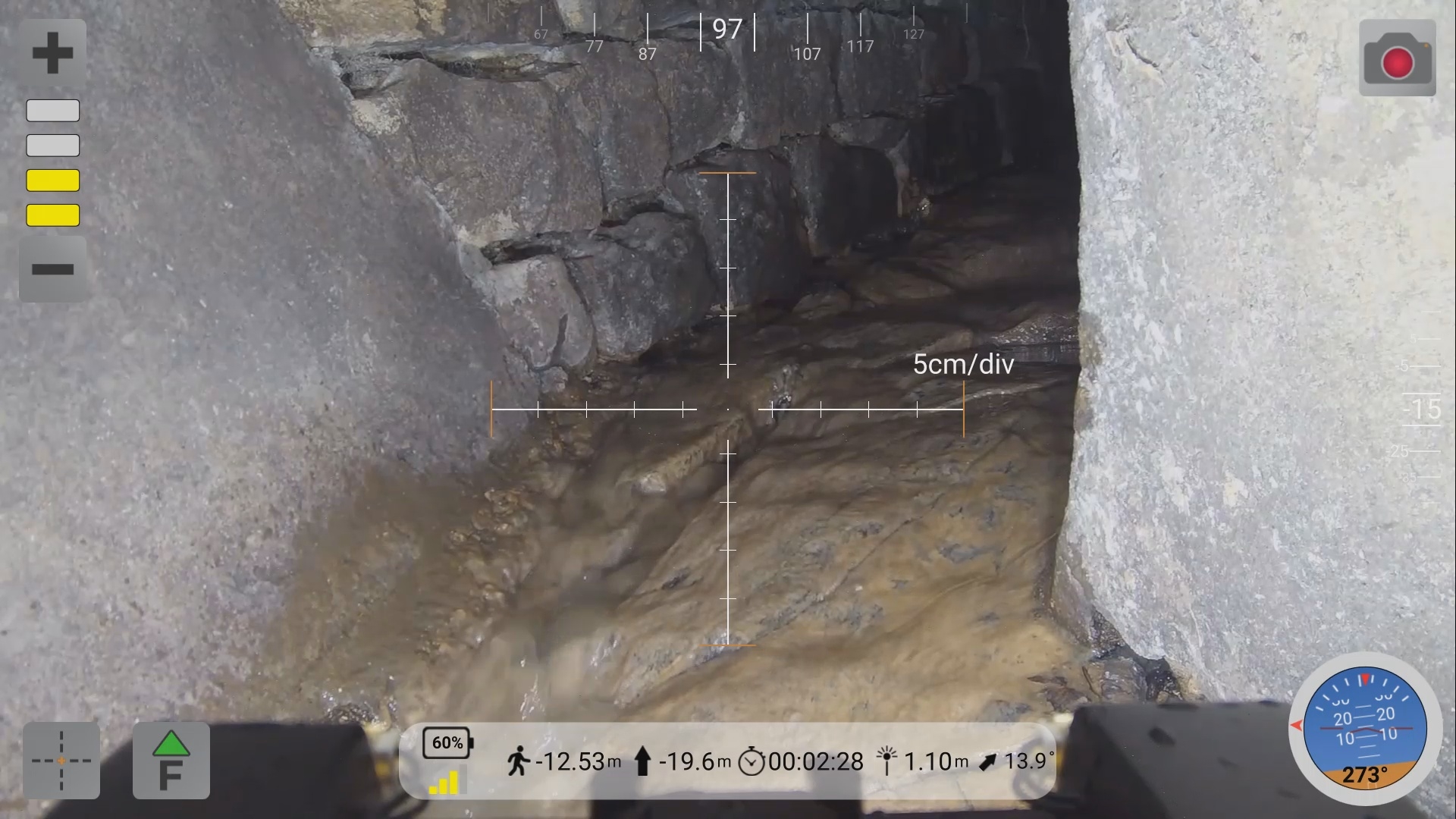

-Roview2 inspection robot: The Roview2, developed by Multinnov, is an inspection robot designed to overcome the challenges posed by pipes of all sizes. It is equally well suited to non‑visitable and visitable pipes, where it can replace human intervention to minimize risks. The versatile Roview2 can travel on the ground or on the water surface in partially‑filled pipes, ensuring complete coverage even in complex conditions.

Equipped with high‑resolution cameras, the Roview2 transmits images and video in real time, enabling detailed analysis and early detection of problems such as cracks, obstructions or signs of wear. This ability to deliver quality images and autonomous movement means that inspections can be carried out faster and more efficiently.

Modern technologies, and in particular inspection robots such as the Roview2, facilitate continuous monitoring and preventive maintenance of pipe networks, limiting the exposure of human agents to risks, and offering accuracy far superior to traditional methods.

Comparison of methods for visitable and non‑visable pipes

Pipe inspection methods vary according to accessibility and operator safety, but inspection robots like the Roview2 are an essential solution in both cases.

-Inspection of visitable pipes: Although these pipes are accessible to human operators, companies now prefer to use robots to minimize the risk of accidents. The Roview2, for example, is capable of navigating visitable sections while providing high‑precision images and data, without the need for direct human intervention. Robotic inspections ensure complete visual coverage while maintaining the safety of maintenance teams.

-Inspection of non‑visitable pipes: Non‑visitable pipes require a stand‑alone device capable of inspecting sections inaccessible to humans. The Roview2, designed to navigate in confined spaces and move on the surface of the water, is the perfect solution. Thanks to its high‑definition cameras and flexibility of movement, it provides optimum visibility in sometimes extreme conditions. This modern technology compensates for the limitations of traditional methods and ensures a complete inspection of infrastructures.

The Roview2's versatility and ability to adapt to different inspection conditions make it an invaluable tool for network upkeep and maintenance, regardless of pipe size or accessibility.

Pipe inspections are essential to guarantee the safety and reliability of distribution and wastewater networks. The distinction between visitable and non‑visitable pipes is a key criterion guiding the choice of inspection methods and technologies. Although visitable pipes can theoretically be inspected by human agents, robots like the Roview2 offer a safer and more efficient alternative, limiting the risk of accidents while ensuring a complete inspection.

Multinnov's Roview2 solution enables autonomous inspection of pipes of all sizes. Thanks to its ability to navigate on the ground and on the surface of the water, it covers all critical areas, even in the most difficult conditions. This advanced technology provides detailed images and accurate analysis, contributing to preventive maintenance and infrastructure sustainability.

By choosing Multinnov solutions, infrastructure managers are investing in reliable, high‑performance tools designed to deliver quality inspection and ensure the longevity of their pipe networks.

:strip_exif()/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/7e1d7cf8-a2df-11ed-b843-0242ac14000b/1-1-multinnov-pour-fond-blanc.png)

:strip_exif()/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/7e1d7cf8-a2df-11ed-b843-0242ac14000b/1-1-multinnov-pour-fond-blanc.png)

/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/dc1f8834-9c28-11ef-8036-0242ac120013/1-1-design-sans-titre-31.png)

/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/e450df62-9de5-11ef-8deb-0242ac120013/1-1-capture-d-ecran-2024-11-08-103326.png)

/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/2410fe10-8e8e-11ee-b27d-0242ac12000c/2-2-pipe-inspection.jpg)