/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/8386b500-9a96-11ef-bf25-0242ac120013/1-1-2.jpg)

Roview2 autonomy and range: what you need to know

Roview 2 coverage distance

Inspections of sewer networks and underground infrastructures require reliable, robust solutions capable of covering long distances. In this context, the distance covered by an inspection cart is one of the essential criteria for ensuring a complete and efficient assessment. Indeed, while a traditional wired ITV cart can cover distances of 50 to 150 meters, it is quickly limited by obstacles and bends, which are common in these complex networks.

The Roview 2, with its wireless operation and extended range, is the ideal alternative for long‑distance inspections. It eliminates cable constraints, crosses obstacles more easily and offers a range of up to 500 meters in concrete networks and 1 to 2 kilometers in metal pipes. Find out how the Roview 2 optimizes inspection operations and why it's the ideal choice for sanitation and industrial professionals.

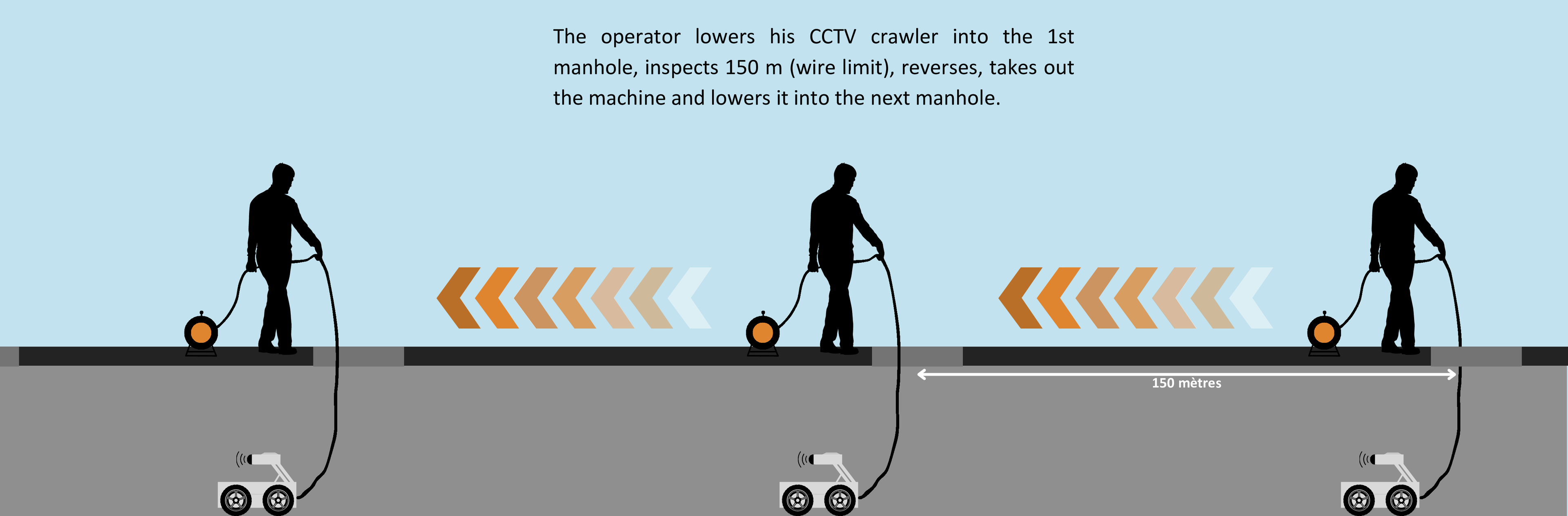

Limitations of wired ITV trucks for network inspections

Limited maximum distance

Wired ITV carts are still widely used for pipeline inspections. However, their range is limited by the cable connecting them to the operator. In general, these carts can cover a maximum distance of 50 to 150 meters. For small to medium‑sized networks, this may be sufficient. But when it comes to larger networks, such as those found in industry or large urban infrastructures, this distance quickly becomes an obstacle.

What's more, these carts require constant cabling, which means the operator often has to manually reposition them to cover the entire length of the pipes. Not only does this slow down inspection, it also increases operational and logistical costs.

Sensitivity to bends and obstacles

Pipe networks are rarely straight, and include numerous bends and other obstacles. With a wired cart, the slightest bend represents a stress point for the cable, increasing the risk of blockage. In some cases, the cable itself can jam, requiring manual intervention to free the cart. These frequent interruptions slow down inspection and increase the risk of damage to the equipment.

The Roview 2, on the other hand, eliminates this type of constraint by operating wirelessly, enabling it to cover much longer distances, even in winding pipes.

Distance covered with Roview 2: an ideal solution for wastewater networks

Performance in concrete networks

The Roview 2 is designed to deliver optimum performance in a variety of environments, including concrete sewer networks, which are very common in urban infrastructures. In these concrete pipes, the Roview 2 can cover a maximum distance of 500 meters in a straight line, without interference or signal loss. This represents a considerable advantage, since inspecting 500‑meter segments in a single operation reduces the number of access points required and, consequently, inspection time and costs.

In a typical sewer network, the inspector can deploy the Roview 2 from an access point, then guide it over a distance of 500 meters before having to reposition the device or use a signal amplifier to extend the range. This capability enables longer sections to be covered in less time, while minimizing the risk of interruptions.

Extended range in metal pipes

In metal penstocks, often found in the industrial sector, the Roview 2 is capable of reaching much greater distances, from 1 to 2 kilometers. Metal pipes, unlike concrete ones, offer more stable signal transmission, making long ranges possible. This capability makes it possible to inspect major industrial infrastructures in a single pass, reducing handling and improving overall inspection efficiency.

This extended reach is particularly advantageous in industries requiring regular, detailed inspections, where production stoppages are costly. By covering distances of 1 to 2 kilometers in a single operation, the Roview 2 minimizes downtime, while ensuring exhaustive quality control of installations.

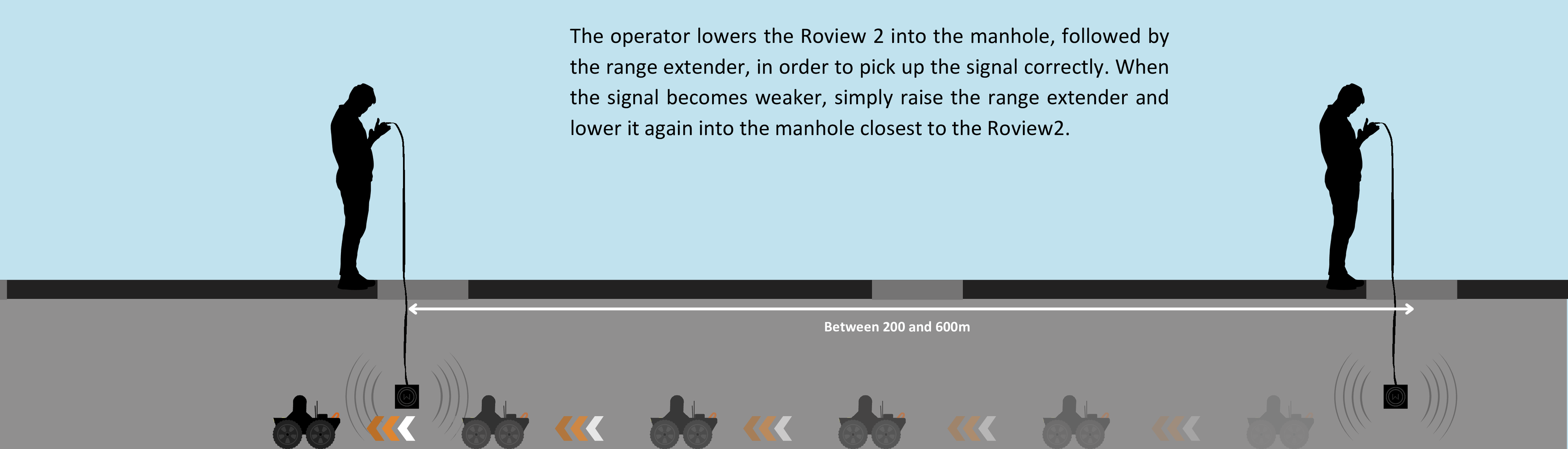

Optimizing inspection times: using the Range Extender

One of the major advantages of the Roview 2 is that it can be coupled with a Range Extender, extending the range of the device without the need for additional cables. Unlike a conventional wired ITV cart, which requires the robot to be lowered into each manhole to cover the entire pipe, the Roview 2 optimizes each inspection stage. With a wired cart, the operator lowers the robot into the first manhole, inspects up to the limit of the cable, then returns the robot to the starting point before repositioning it in the next manhole. This operation is repeated for each section, increasing the time and effort required.

With the Roview 2 and its Range Extender, the process becomes much more efficient: the inspector first lowers the Roview 2 into the first manhole, places the Range Extender to reinforce the signal, then performs the inspection up to the second manhole without needing to return the robot to the first point. Once the distance has been covered, the Roview 2 remains in the pipe, with the operator simply repositioning the Range Extender in the second manhole to continue the inspection to the next point. This approach avoids unnecessary

for the robot, limiting handling to repositioning the Range Extender and maximizing inspection quality.

The benefits of long inspection distances for industry

The advantages of the long inspection distance offered by the Roview 2 are not limited to time savings. Here are just a few of the other key benefits for companies and wastewater network managers:

- Reduced intervention costs: With fewer repositionings, crews spend less time in the field, and inspections are completed more quickly, lowering the costs associated with each intervention.

- Increased safety: By minimizing manual intervention and material handling, the Roview 2 reduces risks for operators, who don't need to descend frequently into manholes to reposition the robot.

- Optimization of resources: with ranges of up to 2 kilometers, inspections are streamlined and enable more efficient use of human and material resources.

Roview 2, a valuable ally for long‑range inspections

Thanks to its ability to cover long distances, whether in concrete sewer networks or industrial metal pipes, the Roview 2 is a reliable and efficient solution for underground inspections. By eliminating the limitations of wired ITV carts, it enables fast and safe long‑range inspections, with a significant reduction in costs and time.

The ability to use Range Extenders in conjunction with the Roview 2 offers additional flexibility, turning this inspection robot into a valuable asset for network managers and industrialists alike. By opting for the Roview 2, companies can not only reduce their inspection costs, but also ensure more precise and proactive predictive maintenance of their facilities.

:strip_exif()/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/7e1d7cf8-a2df-11ed-b843-0242ac14000b/1-1-multinnov-pour-fond-blanc.png)

:strip_exif()/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/7e1d7cf8-a2df-11ed-b843-0242ac14000b/1-1-multinnov-pour-fond-blanc.png)

:strip_exif()/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/2d1bc50a-a30a-11ed-b140-0242ac14000b/1-1-img132.jpg)

/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/0356b896-f35a-11ee-9e20-0242ac120013/2-2-inspection-drone.jpg)

/reboot/media/95268e66-9e53-11ed-b306-0242ac14000b/58f644ac-5628-11ef-83ef-0242ac120012/1-1-p1002011.jpg)